For the production of sintered products in metallurgical, electrical, aeronautical, automotive, machine-building industries (brushes for electric machines, parts made of copper powder-based dispersion-hardened composite materials, conductive tips and electrodes for welding, soldering iron tips, heavily loaded dry sliding bearings).

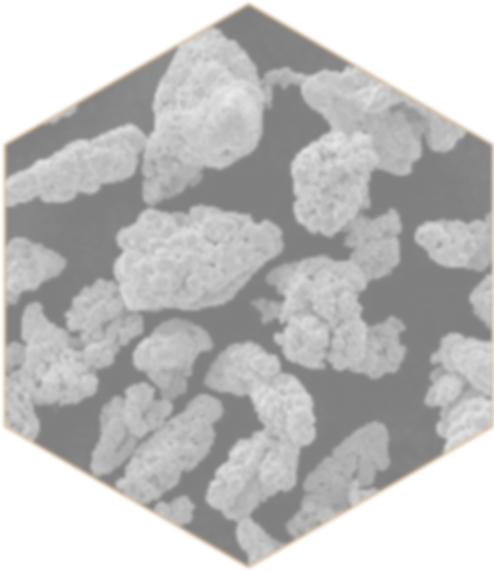

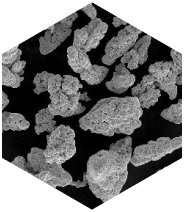

Particle structure

|

Grid size |

Particle size, µm |

Particle size distribution, % |

|||||||

|---|---|---|---|---|---|---|---|---|---|

|

CPR-A |

CPR-B |

CPR-C |

CPR-D |

CPR-E |

CPR-F |

CPR-G |

CPR-H |

||

|

600 |

≥600 |

– |

– |

– |

– |

– |

– |

– |

3 max |

|

300 |

≥300 |

– |

– |

– |

– |

– |

– |

3 max |

10-40 |

|

250 |

≥250 |

– |

– |

– |

– |

– |

– |

15 max |

– |

|

212 |

≥212 |

0.5 max |

0.5 max |

– |

– |

– |

– |

– |

50-80 |

|

180 |

≥180 |

5 max |

2 max |

0.5 max |

– |

– |

– |

– |

– |

|

150 |

≥150 |

– |

– |

1 max |

0.5 max |

0.5 max |

– |

60-90 |

– |

|

106 |

≥106 |

25-45 |

10-30 |

6 max |

3 max |

2 max |

0.5 max |

– |

– |

|

75 |

≥75 |

– |

– |

– |

10-20 |

10 max |

– |

97 min |

97 min |

|

<75 |

– |

– |

– |

– |

– |

– |

3 max |

3 max |

|

|

63 |

≥63 |

60-80 |

45-65 |

30-40 |

– |

– |

10 max |

– |

– |

|

45 |

≥45 |

75-95 |

65-85 |

50-60 |

50-60 |

35-45 |

15-35 |

– |

– |

|

<45 |

5-25 |

15-35 |

40-50 |

40-50 |

55-65 |

65-80 |

– |

– |

|

|

Apparent density, g/cm3 |

2.25-2.55 |

2.1-2.5 |

1.8-2.2 |

2.4-3.2 |

|||||

|

Copper mass fraction, %, min |

99.7 |

99.6 |

|||||||

|

Oxygen mass fraction, %, max |

0.2 |

0.25 |

|||||||

Note: in the particle size value, “<” represents undersize material, “≥” represents oversize material